Liquid Silicon Rubber(LSR)

Liquid Silicone Rubber (LSR) technology is a versatile material used extensively in various industries, including automotive applications. LSR is typically molded into parts using injection molding processes. This allows for complex shapes and precise dimensions, which is crucial for automotive components. LSR offers excellent flexibility and durability, making it ideal for applications where parts need to withstand repeated stress and strain.

Automotive Applications:

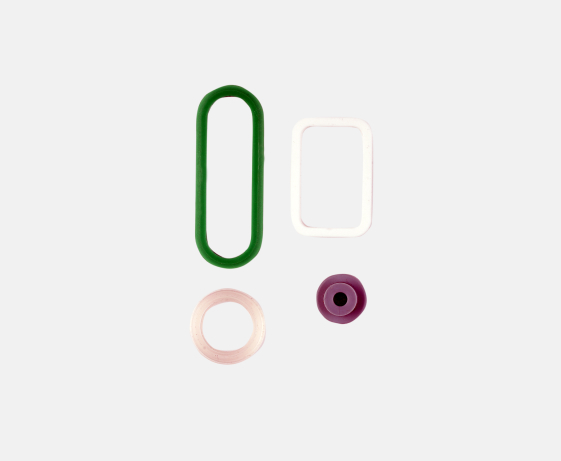

1. Seals and Gaskets:

- LSR is used extensively for manufacturing seals and gaskets in automotive engines, transmissions, and other critical systems. Its durability and resistance to heat and fluids make it suitable for these applications.

2. Grommets :

- Components such as grommets benefit from LSR’s ability to maintain elasticity and seal tight under various conditions, contributing to the reliability of automotive electrical and fluid systems.

3. O-Rings and Dampers:

- LSR is also used in producing O-rings and dampers that absorb vibrations and shocks in automotive suspension and steering systems. Its stable properties over a wide temperature range enhance the performance and longevity of these components.

4. Clutch Boots

- In the automotive industry, LSR clutch boots play a critical role in maintaining the performance and longevity of clutch systems.

In summary, LSR technology plays a crucial role in automotive manufacturing, providing durable, flexible, and reliable components that enhance vehicle performance and longevity across various applications

Applications

Clutch Boot

O Rings, X Rings

Clutch Boots