Sealing System

Sealing system refers to a system or mechanism used to prevent the passage of substances (such as fluids, gases, or contaminants) between two enclosed spaces.

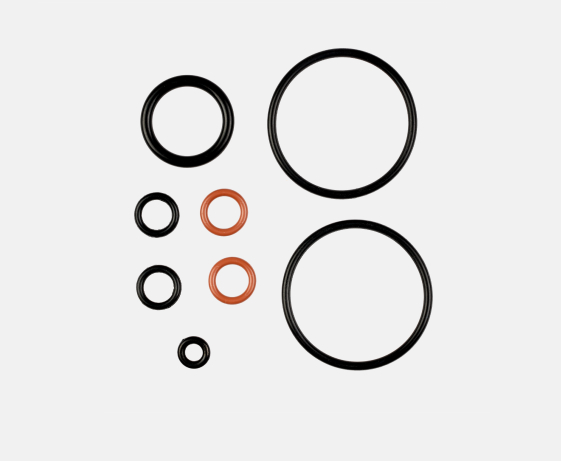

Sealing Parts including O-rings, Seals & Gaskets are essential components in a wide range of industrial applications to prevent leakage and maintain pressure.

Gaskets are flat seals that are placed between two mating surfaces and are typically made of materials such as rubber, silicone, or metal. O-rings are circular seals that are placed in a groove and compressed between two mating surfaces to create a tight seal.

Sealing systems are used in various industries, including automotive, aerospace, oil and gas, and manufacturing. They play a crucial role in ensuring the integrity of systems and equipment by preventing the leakage of fluids or gases. Proper selection and installation of gaskets and o-rings are essential to maintain efficiency and reliability in industrial operations.

There are different types of gaskets and o-rings available to suit specific applications, including high temperature, high pressure, and corrosive environments. It is important to consider factors such as material compatibility, temperature range, pressure rating, and chemical resistance when selecting sealing components for a particular application.

Oil seals, also known as grease seals or shaft seals, are essential components in various mechanical systems to prevent the leakage of lubricants such as oil or grease and to keep out contaminants like dirt, water, and dust. They are typically used in rotating and reciprocating machinery where a shaft penetrates a housing or a casing, such as in engines, gearboxes, pumps, and axles

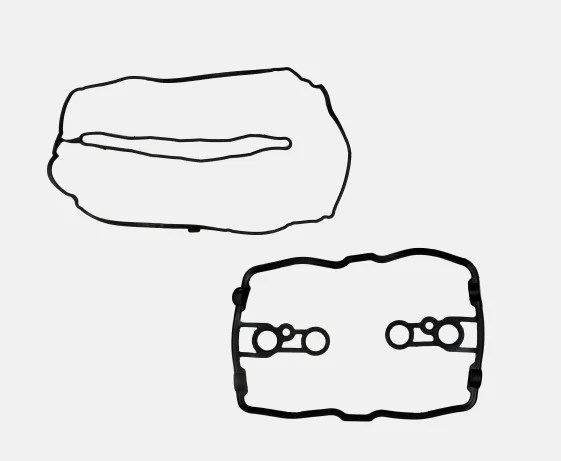

Engine gaskets are crucial components in automobiles that help seal the various openings and surfaces in the engine to prevent leaks. They are designed to withstand high temperatures and pressures, as well as chemical exposures from engine fluids.

Some common types of engine gaskets found in automobiles include head gaskets, intake manifold gaskets, exhaust manifold gaskets, valve cover gaskets, and oil pan gaskets. These gaskets are typically made from materials such as rubber, cork, paper, or metal, depending on the specific requirements of the engine and its components.

When engine gaskets fail, they can lead to oil leaks, coolant leaks, and combustion chamber leaks, which can result in engine damage and poor performance. It is important to regularly inspect and replace worn or damaged gaskets to maintain the proper functioning of the engine and prevent costly repairs.

Overall, sealing systems are crucial for maintaining the integrity and efficiency of industrial equipment and systems, making them a key component in many industries.

Applications

Engine Gasket

O Rings

Oil Seals

Brake Chamber System Seal